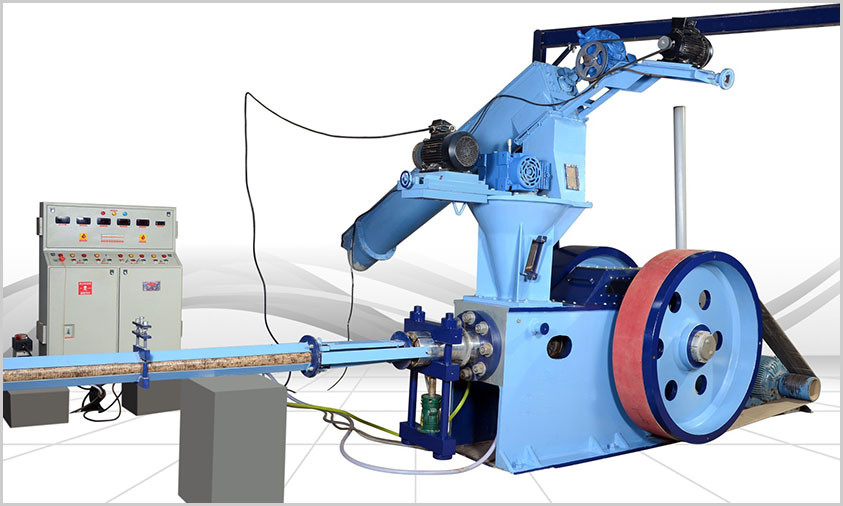

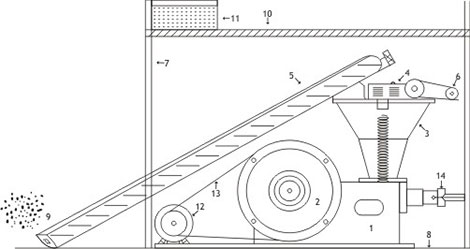

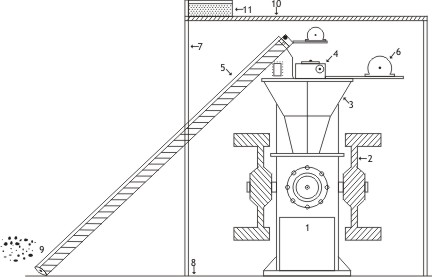

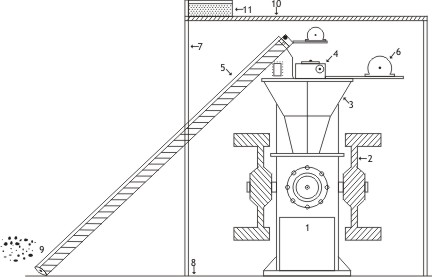

Our new plant JUMBO-90 press produce 90. mm dia. Briquettes. It produces at the ratio of 1500kg / Hrs. It produce Briquettes directly from 20-25 mm size of raw material residuals.

| Model | Jumbo - 90 |

| Type | Crank Type |

| R. P. M. | 230 |

| Production Capicity (+ 20% Depemding on Density and Quality of Raw Material) | 1500 KG/Hr. |

| Finished Product Shape | Cylindrical |

| Raw Material Form | Up to 25mm Size can be Used Directly |

| Stokc | 200 mm |

| Total Power Requirement | 88 HP. |

| Finished Products Size | 90 mm Dia |

| Finished Product Length | 6" to 12" |

The white coal is ideal fuel which substitutes coal, fire-wood, lignite and other conventional fuels for heating steam generation.

The demand of white coal emerges from shortage of conventional fuels like coal, fire-wood arising day by day. So it indicates golden future for white coal and really it is ideal future Fuel.

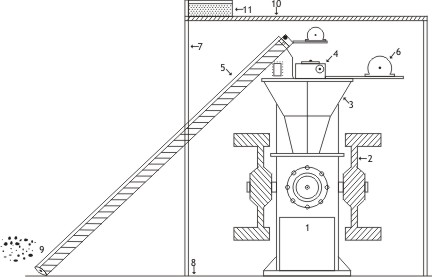

Briquetting plant is a latest equipment in which all types of farming waste and built-up waste are renewed into hard cylindrical form logs using very sky-scraping automatic pressure not including the help of any chemical and element. It can frankly be new as non predictable fuel. Briquetting plant is protects natural cuts toxic waste and saves valuable foreign switch over, also avoid the mistreatment of farming waste and useful to farmers of search out wealth out of their farming waste and get good income by setting up Briquetting plant. Now in India, binder less equipment is the majority well-liked and winning which we have on hand.

Briquetting is the development of densification of biomass to manufacture identical size hard pieces of sky-scraping mass density which can be opportunely used as energy.

Timber is a usual creation which extremely firmed as a briquette approximately takes on the flaming behavior of energy. Owning to their grand thickness timber briquettes has a superior high energy worth than the same number of fuel. It used instead of petroleum or wood in family hard energy stoves as well as in manufacturing furnace.